Successor to SA / SR series

Question

I heard that the SA/SR-20 series (D3-Series) has been abolished.

Which successor should I choose?

Answer

Since the command word system and hardware configuration are fundamentally different between the SA/SR/D3 series and the current S series PLC, there is no direct compatibility, But You can convert SA/SR/D3 series programs to S series programs using “Direct Converter 2”.

It can be converted to a series of programs.

The SA series was a stage style and the SR-Series was a relay stmbol type, and there were two types of CPUs, but the S series is integrated.

“Direct Converter 2” can be downloaded free of charge from our website.

Please select the successor model considering the I/O points, mainly for the D4(SU), D2, and SJ-Ether series.

Note: SA-20 and SR-20 cannot be connected to a PC, so “Direct Converter 2” cannot be used.

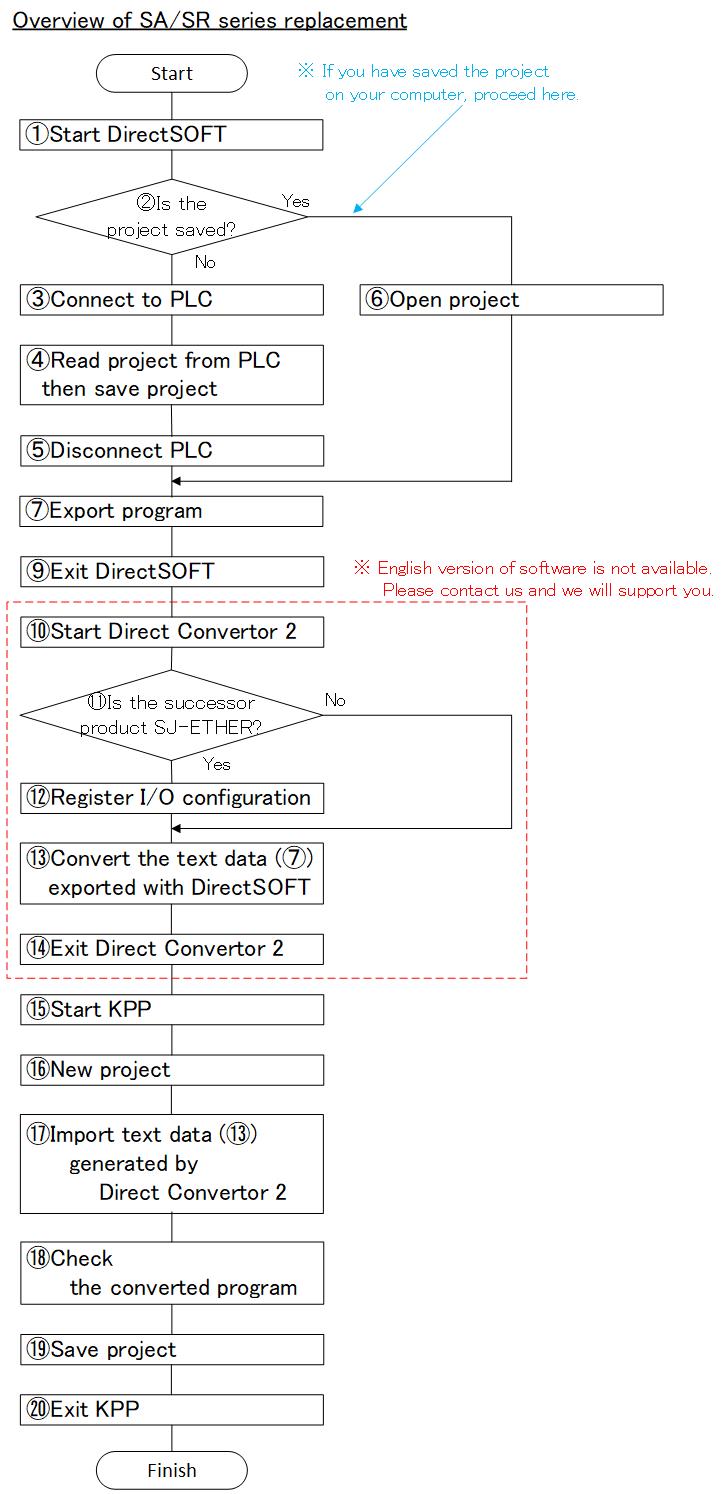

Procedure

Rough procedure

2.Determine the array of PLC I/O modules after replacement.

3.Read the ladder program of SA/SR/D3 series you are using now.

* Since the communication module (D3-232DCU/E-03DM) cannot be used with SA-20 / SR-20,

The ladder program cannot be read to the personal computer.

Sorry for your inconvenience, but visually read by the programmer (A-21P / R-21P)

Please manually enter in DirectSOFT.

Next, replace the CPU with SA-21 / SR-21 and write the ladder program with DirectSOFT.

The procedure after that is the same as SA-21 / SR-21.

4.Convert the ladder program so that it can be used in the replaced PLC.

* Since Direct Convertoe 2 is a Japanese version of the software, please ask us to do this work for you.

5.Replace the PLC.

6.Write the ladder program to the replaced PLC.

7.Check the operation.

Things to prepare

2.Communication cable. (Between PC – D3-232DCU/E-03DM)

3.Communication cable. (Between PC – replaced PLC)

4.If your computer does not have a serial port, use a commercially available USB/serial conversion cable.

Determine the PLC after replacement

Each has advantages/disadvantages.

Please refer to the table below and the simple comparison table to select a replacement model.

| PLC candidate for replacement | Maximum size(mm) | Ease of wiring | Maximum number of I/O points | Cost performance | I/O module comparison table |

| D2 series | 370W x 90H x 92D | 16-point I / O requires change of crimp terminal | 1536 | Good | Click here for comparison table |

| SJ-ETHER | 304.4W x 85.0H x 86.7D | It is necessary to change the crimp terminal | 142 | Very good | Click here for comparison table |

| D4(SU) series | 441W x 150H x D | Good | 2048 | Not Good | Click here for comparison table |

| Reference Information SA/SR/D3 series |

465.0W x 120.0H x 136.0D | — | 168 | — | — |

2.Check the wiring cable length and the PLC installation space after replacement.

– The I/O address of the SA/SR series is from right to left, but the PLC after replacement is the opposite from left to right.

– Check if the length of each cable is sufficient.

– Check whether it is necessary to reprocess the ends of the power cable and I/O cable.

3.Determine the I/O module array of the PLC after replacement.

Read the SA/SR/D3 series program and convert it to the successor model.

Export a program in DirectSOFT

1.Start DirectSOFT.

* If the ladder program is saved, proceed to 3.

2.Connect the SA/SR/D3 series PLC and the computer with a cable, and select “PLC”->”Connect” from the DirectSOFT menu to connect the DirectSOFT and PLC.

Click here for the connection procedure.

3.Read the program from the PLC and save it as a project.

Click here for the procedure to read the program from the PLC.

4.From the DirectSOFT menu, select “PLC”->”Disconnect” to disconnect the DirectSOFT and PLC.

5.From the DirectSOFT menu, go to “File”->”Export”->”Program” and specify the file name to export the program.

6.Exit DirectSOFT.

Convert your project in Direct Convertor

11.Please ask us to do this work for you.

Check the converted program with KPP

21.Start KPP and select “Create new project”.

22.From the KPP menu, go to “File”->”Import”->”Import Program”.

* Set the target to “Program”, select the text file converted in 11, and run it.

23) Check the converted program.If there is an error in 11, correct it.

23.Save the project.

24.Exit KPP.

Write the program to the replaced PLC and check the operation

D2 series is here

SJ-Ether series is here

D4(SU) series is here

Click here for the program writing procedure.

Notes

– There are some parts that cannot be converted correctly with Direct Convertor.

– Please make sure that there are no differences between the programs before and after conversion.

– If you have any other questions regarding replacement, please feel free to contact us.

Inquiry

Click here for inquiries by email